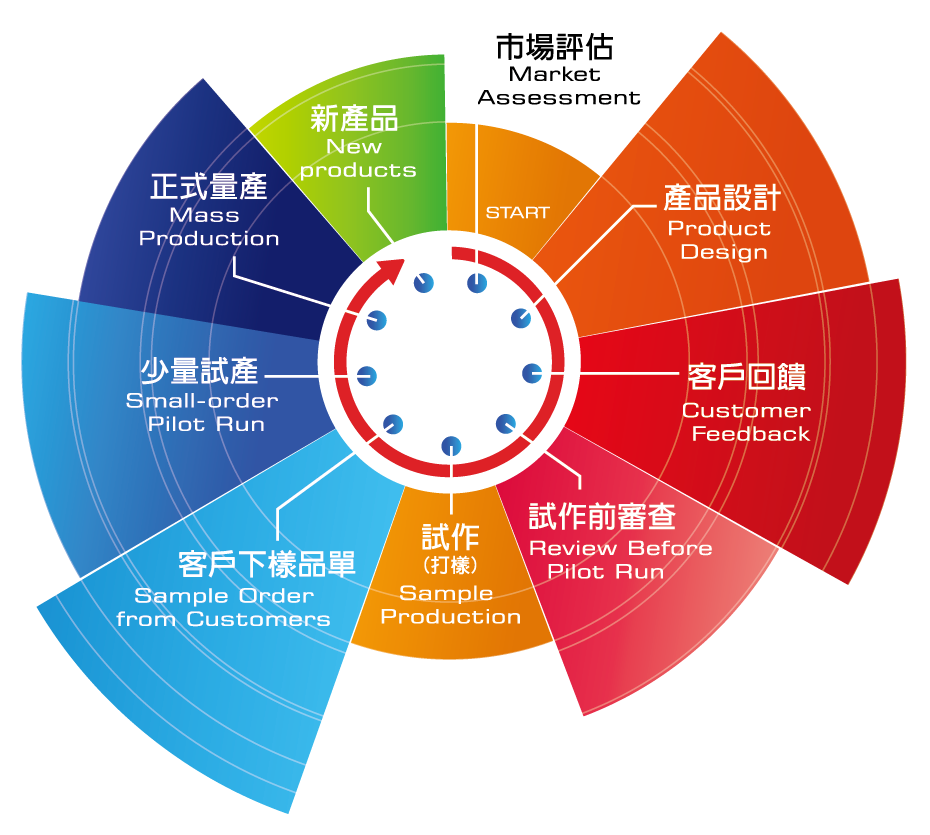

裕偉要求金屬與塑膠的結合搭配,是對委專案的全盤性了解後,傾聽客戶的需求與市場資訊,將競爭條件需求與產量做結合,加入價值工程分析,最後融合企業發展策略考量,做為創新的方向與執行。

著重3D數位模擬技術,讓設計的抽象概念加上人性化角度發展,在與客戶互動溝通過程中能更加順暢,並且累積多種成型技術與經驗,在最短時間內轉換為實體,且更有效率的促進團隊溝通。

與傳統設計不同的是,裕偉在創新的執行上,不僅將產品規劃符合設計元素要求及實用性,更重視量產的可行性,正是「不能順暢量產的產品設計,就不能稱為好設計」,裕偉的設計團隊格外重視量產整合能力,不論是開發前後段專業資源、生產線品質與精度要求,都是為客戶設想的優先關鍵。

Design + Engineering VA/VE Analysis + Product Innovation

YUEN WEI requires the combination of metal and plastic, based on a comprehensive understanding of the commissioned project, listening to customer needs and market information, and combining competitive conditions and production requirements. Value engineering analysis is added, and finally, it is integrated with the consideration of enterprise development strategy as the direction and execution of innovation.

Direct observation and communication of design performance Emphasis is placed on 3D digital simulation technology, allowing abstract design concepts to be developed from a human perspective. In the process of interacting with customers, it can be more smooth and accumulate a variety of molding techniques and experience to be converted into reality in the shortest possible time, and promote team communication more efficiently.

Design for manufacturability

Unlike traditional design, YUEN WEI not only plans products to meet design element requirements and practicality, but also emphasizes the feasibility of mass production in innovative execution. It is precisely that "product design that cannot be smoothly mass-produced cannot be called good design." YUEN WEI's design team attaches particular importance to the integration capability of mass production, including professional resources before and after development, production line quality, and precision requirements, which are all prioritized for customer considerations.